| Wastewater Processing

& Wastewater Effluent Recycling | WWR

System Construction & Operation | FAQ

| Examples | Municipal

System Clusters

WWR-M2.5K Collage | Building

EWWRU-M20K | WWR Cost Sheet

WWR

SYSTEM CONSTRUCTION & OPERATION WWR

SYSTEM CONSTRUCTION & OPERATION

UNIT CONSTRUCTION AND OPERATION - GENERAL OVERVIEW

(Patent Pending)

The GLOBAL WASTEWATER-RECYCLING SYSTEM utilizes the extended aeration

method of sewage treatment. Five separate operations are involved

in this process.

The

first operation is a coarse screening process. The

first operation is a coarse screening process.

As the influent enters the sewage treatment unit, it passes through

a BAR SCREEN . The bar screen will catch any large trash such as

rags, plastic bags, etc., and prevent it from entering the system.

[In existing, conventional facilities, Global utilizes whatever

pre-screening and/or separating equipment that is useable, as the

basic quote includes delivery from the city to the Global system.

However, when necessary, Global will replace screeners, pre-filters,

grinders and pumps. Also, the first operation may include a surge

tank to control abnormal influent flow rates.]

The second operation is aeration.

As the sewage passes through the bar screen, it flows into the

AERATION CHAMBER . The aeration chamber is the largest component

of the sewage treatment system, and is usually sized to provide

a 12-hour retention time for the daily average flow volume of sewage.

In the aeration chamber, the incoming raw sewage is mixed with water

that contains a large concentration of very active aerobic bacteria

that consume the organic waste material in the sewage. Air flowing

up through the liquid from the DIFFUSER keeps the bacteria in suspension,

and also provides the necessary amount of oxygen required by the

bacteria for their respiration and digestion process. The airflow

through the liquid also provides the agitation necessary to keep

solids from settling on the bottom and helps break up solid waste

material in the sewage.

The bacteria in the aeration chamber will stick together in little

flakes of sludge called a biofloc or floc that becomes uniformly

mixed in with the water as a result of the agitation caused by air

flow from the diffusers. This floc cannot be discharged from the

unit, because it is also an organic pollutant. However, it is easy

to physically separate the floc from the water during the treatment

process. This separation process is the third operation.

The third operation consists of

clarification and settling.

After the usual 12-hour average retention time in the aeration

chamber, all liquid is displaced eventually by additional sewage

flowing into the sewage treatment unit. The displaced liquid flows

around a baffle and through an opening into a separate chamber called

the CLARIFIER . The clarifier is volumetrically sized to ensure

solids settling separation from the liquid.

In contrast to the liquid in the aeration chamber, the liquid in

the clarifier is kept as still as possible to allow the sludge to

flocculate and settle to the bottom. This settling process separates

the sludge from the clear liquid flowing downward and upward around

the clarifier baffle. The clear liquid at the top of the clarifier,

outside the clarifier baffle, is also eventually displaced from

the clarifier over a WEIR, disinfected and then discharged.

The sludge or floc that has settled to the bottom of the clarifier

is continuously drawn up by the airlift SLUDGE RETURN line and discharged

back into the aeration chamber.

Any floating material in the liquid flowing into the clarifier

is contained by the CLARIFIER BAFFLE, and then it will be eventually

drawn into the SKIMMER RETURN LINE. The floating material is then

discharged back into the aeration chamber.

Both the skimmer and sludge return lines operate by using air from

the air supply system. The air is injected into both the skimmer

and sludge return lines. As the resulting air bubbles rise, they

displace the liquid in the lines. This displacement develops a suction

at the inlet to each line.

The unit air supply is a critical requirement for unit operation.

If the unit air supply is inadequate, not only will the bacteria

in the aeration chamber die off or become anaerobic, but also the

skimmer and sludge return will stop operating as required. The unit

air supply is provided by a BLOWER SYSTEM incorporated into the

total system.

Inadequate air supply to the aeration chamber diffusers will also

result in the growth of anaerobic bacteria that will release odor-causing

gases.

Thus, air supply control is one of the few constants in maintenance

procedures.

The fourth treatment operation is

the recycling of suspended solids.

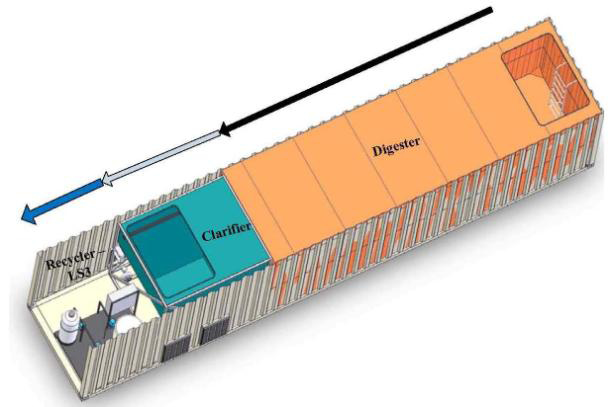

The effluent flowing from the clarifier is then placed in a holding

tank for input into the Global Recycling Process. This effluent

will still have suspended solids and high e-coli. GLOBAL’S

LS3-Recycling-Water System (“LS3-RECYCLER”) shall have

a pre-filtration process to separate and collect all suspended solids

(TSS).

The LS3-RECYLER shall pull from the Clarified Holding Tank. This

process shall be automated. The Recycler shall collect all TSS for

backwashing discharge. This discharge should be piped back to the

Aeration Chamber for black-water processing. The backwash system

shall include a backwash tank which shall be automatically re-filled

after backwashing.

The fifth treatment operation is

the water purification process.

The LS3-RECYCLER shall process the effluent through a standard

Global-LS3 Water purification system. The effluent, removed of all

suspended solids down to 10-Microns, will flow through a 5-Micron

filtration and then 1-Micron filtration to remove parasites.

The next process will be through Global’s proprietary multi-media

adsorption and absorption formulation to remove hazardous chemicals.

From there, the effluent passes through an Ultra-Violet (UV) component

to kill bacteria and viruses. The water output shall equal or exceed

all WHO and International-EPA standards.

Wastewater Processing &

Wastewater Effluent Recycling | WWR System

Construction & Operation | FAQ

| Examples | Municipal

System Clusters

WWR-M2.5K Collage | Building

EWWRU-M20K | WWR Cost Sheet |